I have had a Ruida laser now for a couple of years,1200 x 900,100W CO2.

Generally very pleased with it,mechanically well built,optics look good.

I have noticed what I think is a gradual decrease in power and wonder what is the most accurate method for determining power output at the sharp end?

I look forward to your replies.

Thanks in advance.

Keith

Hello Keith

A fading power is usually a sign that the tube is on its way out. What you tend to get is a good cut at the beginning to a path then it tails off. However in my experience 80% of the time reduction in power are due to one of several factors.

- Alignment - ensure that your mirrors are consistently aligned across the machine including down through the lens and out the little hole.

- Bed leveling is the work actually level across the whole machine?

- Coolant, is there plenty of water and is it flowing well through your tube?

There are a number of laser power probes on the market. We’re actually working on one right now at Smoke & Mirrors (my company) but its not quite ready yet.

Where are you based? If you want to drop me an email off list dominic@smokeandmirrors.store I’d be very happy to see if I can drop by and test the power for you with my probe (not a euphemism).

Short of that I also sell laser tubes and laser cutters.

Dominic Morrow

@chickengrylls

Thank you for the reply.

The machine had sat unused in a heated,dry garage for several months and when I came to use it the cuts were good albeit on a higher power than I would have expected.

The next day it wouldn’t cut.Higher power,different material,no joy.It will scan,dot at various settings but cutting is a problem.Bed is level and beam central on all lenses.I am going to clean the lenses now to see whether that improves things.

I am in NW England-are there any laser engineers in the Liverpool area?

If it is the tube,I won’t be amused-it’s only two years old and hasn’t been worked to death.

Regards

Keith

Hello Keith

I was in Liverpool just a week or two ago! Oh well. I will be back at some point in the not to distant future.

A central alignment is all well and good but its consistency that is key though. It hitting the middle of every mirror is fine, does it hit in the same place wherever it is in the work area? As mentioned before, check you are getting a full clean dot downward through your lens and out the little hole below it. Honestly, the most common problem I’ve seen is the beam hitting the little cone below the lens and causing a reduction in power. I’ve no idea what system you have so it’s hard to say if this is likely for you. I made a video about this topic:

https://www.youtube.com/watch?v=Y89P9a0HI0U&t=11s

and another on alignment generally

https://www.youtube.com/watch?v=2yHAP8A0IG4

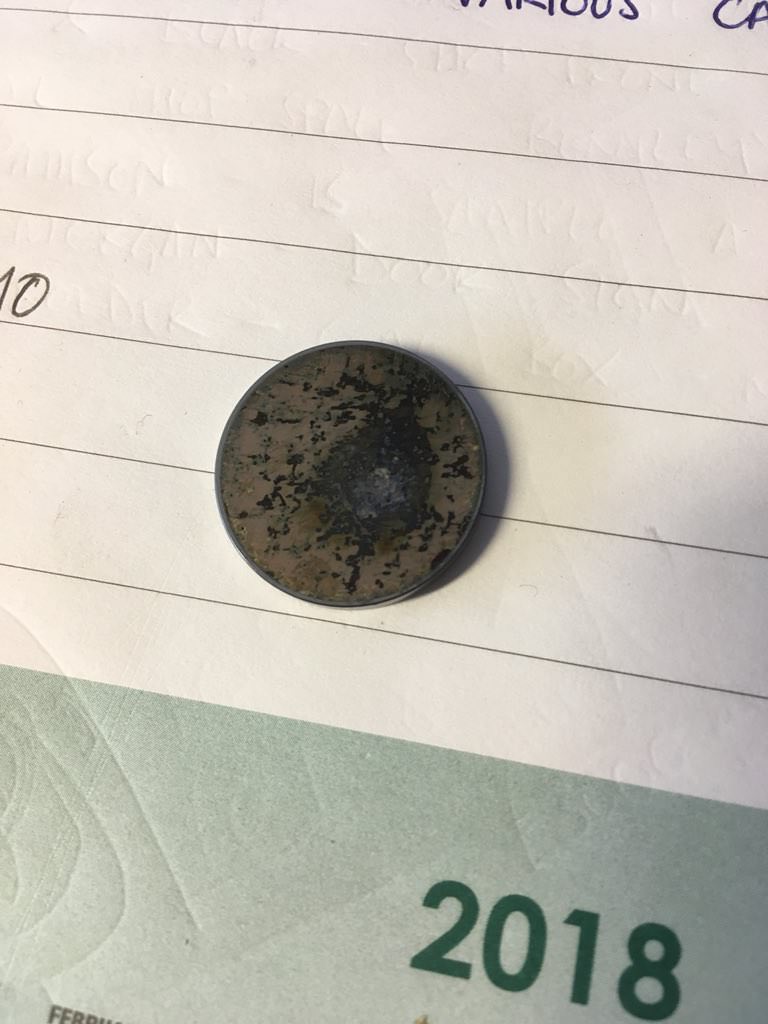

Honestly the number of times folks have asked me about upgrading their laser tube and it turns out to be because they haven’t aligned it. Actually remind me, just last week, a customer was asking me about how to fit a new tube then they sent me this picture of their mirror:

So yes, visually check your lens and mirrors, mirrors should give a clean clear reflection when you shine a torch on them, i.e. not tarnished or smeared. Rub them with a glasses /lint free cloth, if stubbornly dirty use acetone or IPA (not the beer) to clean them finishing with the glasses cloth again. Also make sure your lens is clean and in the right place, level and with the curved side towards the sky and the flat side towards your work (although this wouldn’t matter that much).

It’s interesting that you’d be annoyed about the tube not working after only two years. There are so many factors around tubes. Common reasons they fail include:

- Cutting at 100% of available power, you should limit cutting to around 65/70% of available power.

- Large amounts of etching/engraving especially on shitty materials

- Poor or virtually no cooling (bucket of stagnant water)

- Bad extraction causing the lens on the end of the tube to get dirty and tarnished

- Air bubbles in the tube causing poor cooling

- (here’s the killer) low activity, the tube needs to be used relatively regularly or they fail, this is anecdotal, I’ve not good data on it, but there is a pattern of people telling me “they hardly use the tube for years” and them failing.

- Machine was horrible and cheap (from eBay or similar) cost less than £1k so the tube is unbranded generic and the cheapest thing ever made and shite.

Let me know how you get on. What machine is it by the way?

Dominic

Hi Keith

What Brand is the tube, makes differ quite considerably, I have had tubes last 8 years and others a few months, There is a company in south wales that will Rent a power meter if you need to test your tube,

I’d tend to agree it’s likely more an issue with tube quality than ageing across the board affecting power. With all the glasswork, feedthroughs, mixed materials and varied pressure envelopes involved… it’s amazing the gas medium doesn’t become contaminated earlier than it does in general.

Hello Wayne

What’s the name of that company? That sounds super interesting. I bet they’re the guys who also re-gas tubes. I’d like to contact them.

Dominic